About

2K TREND, a.s. manufactures plastic parts by injection moulding.

Our company was founded in 2015 by management with more than 20 years of experience in the field of injection moulding and small assembly of plastic parts, mainly for the automotive and electrical engineering industry.

Our domain is the production of technical and dimensionally accurate parts such as gears, threaded nuts and various other technical parts made of plastics.

Quality

2K TREND, a.s. places great emphasis on the final quality of manufactured products and on minimizing possible environmental impacts caused by its production. For this purpose, the company has implemented an integrated management system of the company, including all the requirements of ISO 9001 and IATF 16949 and the basic requirements of ISO 14001.

The company’s IMS certification according to the IATF 16949 standard is planned for 2022.

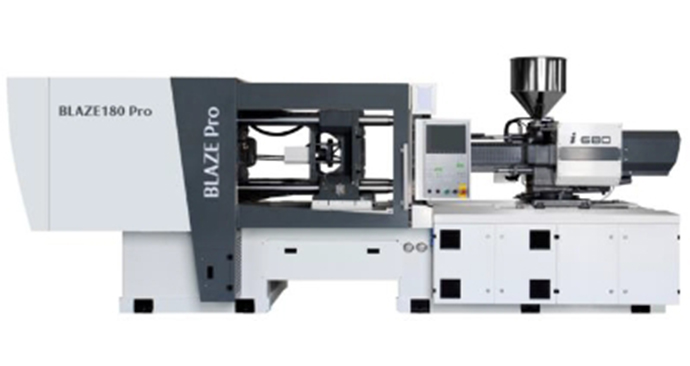

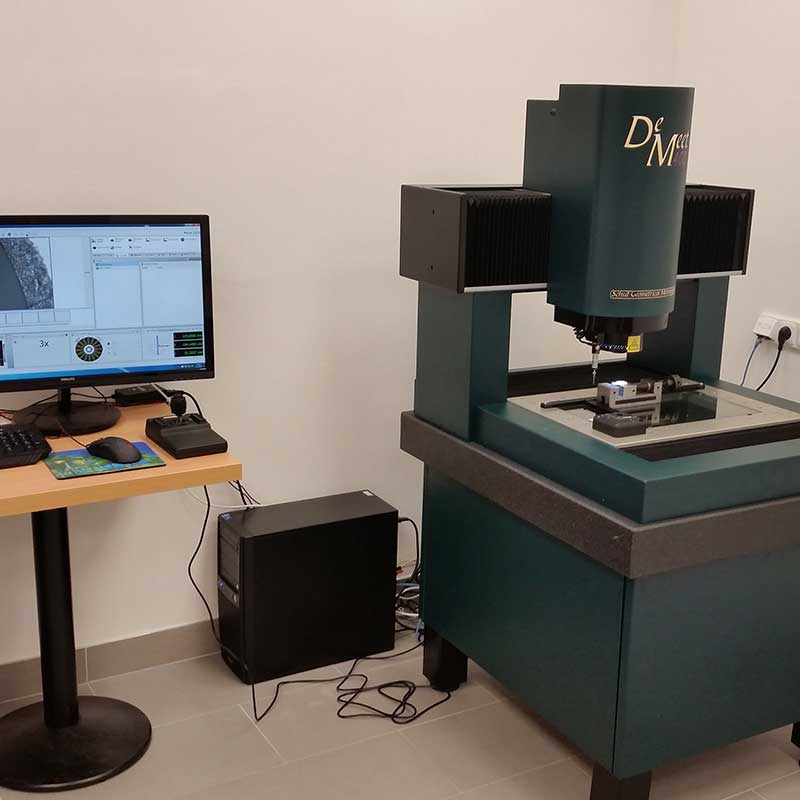

Machinery

Newly built production hall

The newly built production hall meets the parameters of modern pressing shops, including appropriate technological equipment, such as central granulate transport (MORETTO), digitally controlled drying ovens instead of hoppers directly at the entrance to the press chamber (MORETTO), compressor cooling (FRIGOSYSTEM), sophisticated 3D optical and touch gauge (De Meet 400), screw compressor (KAESER), fully automated lines for loading gear shafts and wiper linkages and much more.

Contact

2K TREND a.s.

Podnikatelská 539

190 11 Praha 9 – Běchovice

Company ID: 25275861, VATIN: CZ25275861

Facility – address for delivery

Contact person

Jiří Koláček, director

+420 731 614 601

jiri.kolacek@2ktrend.cz